The food manufacturing supply chain continues to experience unprecedented disruption. It’s creating a ripple effect on food service, grocery stores and consumers who spent about 12% more on food prepared at home in 2022 compared to 2021, the steepest climb since 1979.

The food manufacturing supply chain continues to experience unprecedented disruption. It’s creating a ripple effect on food service, grocery stores and consumers who spent about 12% more on food prepared at home in 2022 compared to 2021, the steepest climb since 1979.

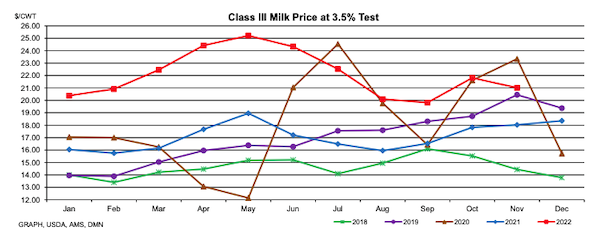

Some markets are affected more than others. The dairy industry supply chain has been plagued by significantly higher transportation costs and delays due to fuel prices and labor shortages. Dairy products are highly perishable and, because of unreliable freight, some producers resorted to dumping their milk at their own expense. These challenges not only create supply chain issues, they also generate extreme price volatility in the dairy industry.

Source: USDA

Source: USDA

The causes of supply chain disruption are varied. However, there are steps that food manufacturers can take to help ensure dairy-based ingredients are there when they need them while also evening out the peaks and valleys of the market.

Ingredient Sourcing, The Key to Supply Chain Reliability

One of the biggest factors in maintaining reliable ingredient supply chains is sourcing. The less distance an ingredient travels to a manufacturing facility, the more reliable that ingredient supplier will likely be. Cross-continental transport of fresh dairy ingredients from California to the East Coast is untenable in today’s market. Sourcing commodity ingredients from outside the United States presents further challenges.

Using locally sourced ingredients has been a mantra of some in the food industry for years and appeals to consumers. Doing so at scale is often difficult for larger ingredient suppliers.

Grande Custom Ingredients Group, a producer of functional whey protein ingredients, hasn’t faced the challenges seen by many other ingredient suppliers due to their innovative approach to sourcing. “We’re fortunate to have dedicated farms that produce milk exclusively for us,” says Britta Campton, Technical Sales Manager at Grande Custom Ingredients Group. “We have an uninterrupted supply and control of the raw ingredients on the front end, and that carries through the entire process, from cheesemaking to the production of our functional whey ingredients.”

RELATED:

Grande Custom Ingredients Group Sustainability Report

Alternative Ingredients Improve Supply Chain Disruption

The quest to minimize fresh cheese and dairy supply chain disruption has led some food manufacturers to seek out other ingredient solutions that provide the same functionality.

“Formulation teams have switched gears in the last year or two and are focused on finding alternative ingredients,” says Campton. “For some, supplies have been totally cut off or reduced, and they need a backup source they can rely on.”

However, the process of looking for alternative ingredient suppliers that can provide assurance of their product quality, functionality and availability is time-consuming and costly. Adding to the challenge is that such a combination of key performance indicators isn’t always easy to find.

Functional whey protein ingredients should be a serious consideration when looking to partially replace costly cream, cheese and other volatile dairy ingredients. In addition to being sourced from dedicated, regional dairy farms in the Midwest, Grande Custom Ingredients Group’s whey protein ingredients have a strict chain of custody designed to ensure the highest levels of consistency and quality.

“Our proprietary products are unlike commodity whey,” says Campton. “We can take 40% of our powdered product mixed with 60% water and get a thick, creamy sauce. Do that with a commodity whey protein and you’ll end up with a thin, grainy fluid. Formulators really need to see it to believe it.”

Two readily available and price-stable ingredients that have made a significant difference for food manufacturers are Grande Bravo® functional whey protein to partially replace high-fat cream, and Grande Gusto® reduced lactose whey as a partial replacement for cheese and cheese powder.

Their functionality sets them apart from other whey products by demonstrating superior water-holding capabilities and clean dairy flavors that are consumer preferred for all key sensory attributes.

“They serve as a single solution that doesn’t require masking agents or additional emulsifiers to create a creamy texture and mouthfeel,” says Campton, “helping to simplify supply chains. And because they’re readily available in powdered form, they have a longer shelf life than fresh dairy and don’t come with many of the associated food safety concerns.”

Work With Trusted Ingredient Suppliers

Food manufacturers routinely change suppliers and switch out ingredients in their formulations to improve product quality or cost savings. Increasingly, they’re being forced to switch some ingredients in pursuit of reliable ingredient sourcing, and Grande Custom Ingredients Group is able to deliver.

Contact the formulation specialists at Grande Custom Ingredients Group to request samples of our innovative whey protein products, and learn more about our chain of custody.